Discover Food Packaging Job Opportunities in Hungary for English Speakers

In Hungary, individuals fluent in English can explore a variety of careers within the food packaging industry. This sector offers insights into flexible working conditions and evolving income trends. As the demand for food packaging jobs continues to grow, understanding the landscape can help prospective candidates make informed career decisions.

Understanding Food Packaging Industry Structure in Hungary

Hungary’s food processing sector encompasses various manufacturing operations where packaging activities occur. These facilities typically handle different product categories including dairy products, processed foods, beverages, and confectionery items. The industry structure includes multinational corporations and domestic companies distributed across different regions.

The sector’s connection to European markets creates some operational requirements for multilingual capabilities, including English proficiency in certain contexts. Companies engaged in export activities may utilize workers who can handle international documentation, communicate with overseas partners, or support global supply chain functions. Actual employment scenarios depend on numerous variables including economic conditions, seasonal factors, and individual company circumstances.

General Characteristics of Food Packaging Work

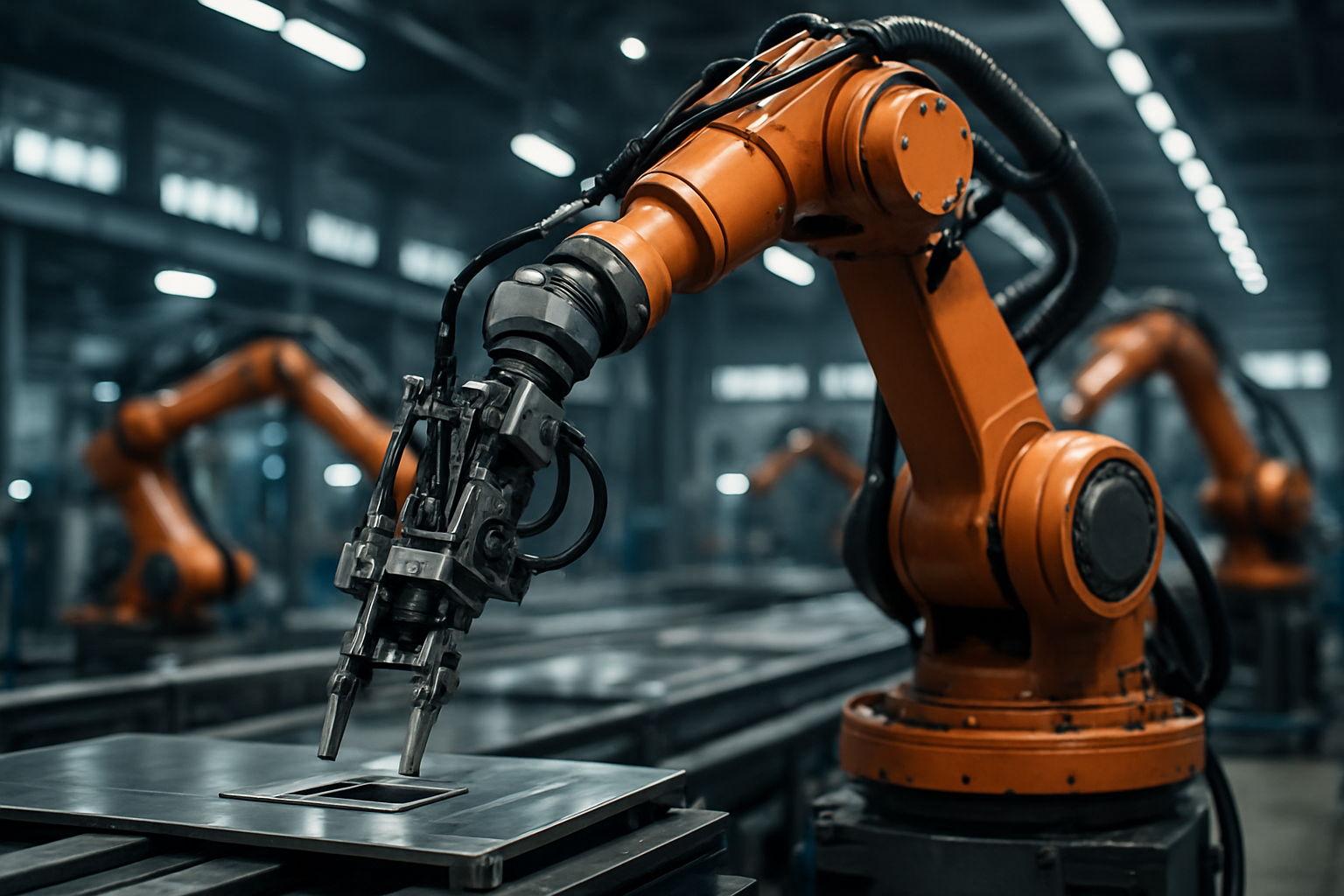

Food packaging roles typically encompass machinery operation, quality inspection processes, and packaging line activities. These positions generally require physical capabilities for standing, manual coordination, and adherence to safety protocols. Work environments usually maintain controlled conditions to meet food safety and quality regulatory standards.

Industrial employment in this sector may include various standard benefits such as health coverage, vacation entitlements, and equipment training programs. Food production often maintains relatively consistent operational patterns compared to more cyclical industries, though employment stability depends on individual company performance and market dynamics. English language capabilities might provide advantages in certain operational contexts, particularly those involving international coordination activities.

Career Development Aspects in Packaging Industries

Professional progression within food packaging sectors can potentially advance from entry-level positions toward supervisory or specialized functions. Companies may implement training programs covering quality assurance methodologies, equipment operation procedures, or production coordination systems. Workers with communication capabilities might encounter opportunities in export operations, customer service functions, or administrative support roles.

Scheduling in food packaging facilities often incorporates various shift arrangements to support continuous production requirements. This operational structure might accommodate different schedule preferences for some workers, though specific arrangements vary significantly by employer and operational needs. Some facilities include seasonal or variable hour positions based on production demands and business cycles.

Employment Research Considerations

Food packaging positions typically require physical capabilities for manual tasks and extended standing periods. Language requirements vary considerably by role type, with some positions requiring minimal communication while others necessitate fluent English for international functions. Employers generally implement interview processes and may include practical assessments of relevant operational skills.

Documentation requirements include proper identification and work authorization for non-EU citizens. Certain positions may require health certifications or background verification depending on employer policies and role specifications. Companies might provide orientation support for workers adapting to Hungarian workplace requirements and procedural systems.

Working Environment Information

Food packaging facilities operate under regulated environmental conditions to maintain product safety and quality compliance standards. Workers typically utilize protective equipment provided by employers, including hairnets, gloves, and safety footwear. Facilities implement hygiene protocols requiring regular sanitization and cleanliness procedures throughout operational periods.

Equipment in contemporary facilities aims to minimize physical strain, though workers should anticipate active engagement during operational shifts. Facilities generally provide scheduled break periods and designated rest areas for employee use. Work environments typically include climate control systems and ergonomic considerations, though specific conditions vary by facility type and product specifications.

This overview provides general information about food packaging industry characteristics in Hungary for educational purposes. Individuals interested in employment research should investigate current market conditions, specific employer requirements, and actual job availability through appropriate employment resources, job boards, and direct company inquiries when making career-related decisions.