Discover Food Packing Work Opportunities in Netherlands

Those who live in Netherlands and speak English can delve into the dynamics of working in food packing warehouses. This sector offers a glimpse into the food packaging industry, highlighting the conditions, expectations, and environments found in warehouses. It serves as a vital component of food processing, packaging, and labeling practices across various cities.

Understanding Food Packaging Operations in Netherlands

The Dutch food packaging sector operates across multiple segments including fresh produce, dairy, meat processing, ready-made meals, and confectionery products. Operations typically involve several stages: receiving raw materials, quality inspection, processing, packaging, labeling, and preparing for distribution. Most facilities run on shift-based systems to ensure continuous production throughout the day.

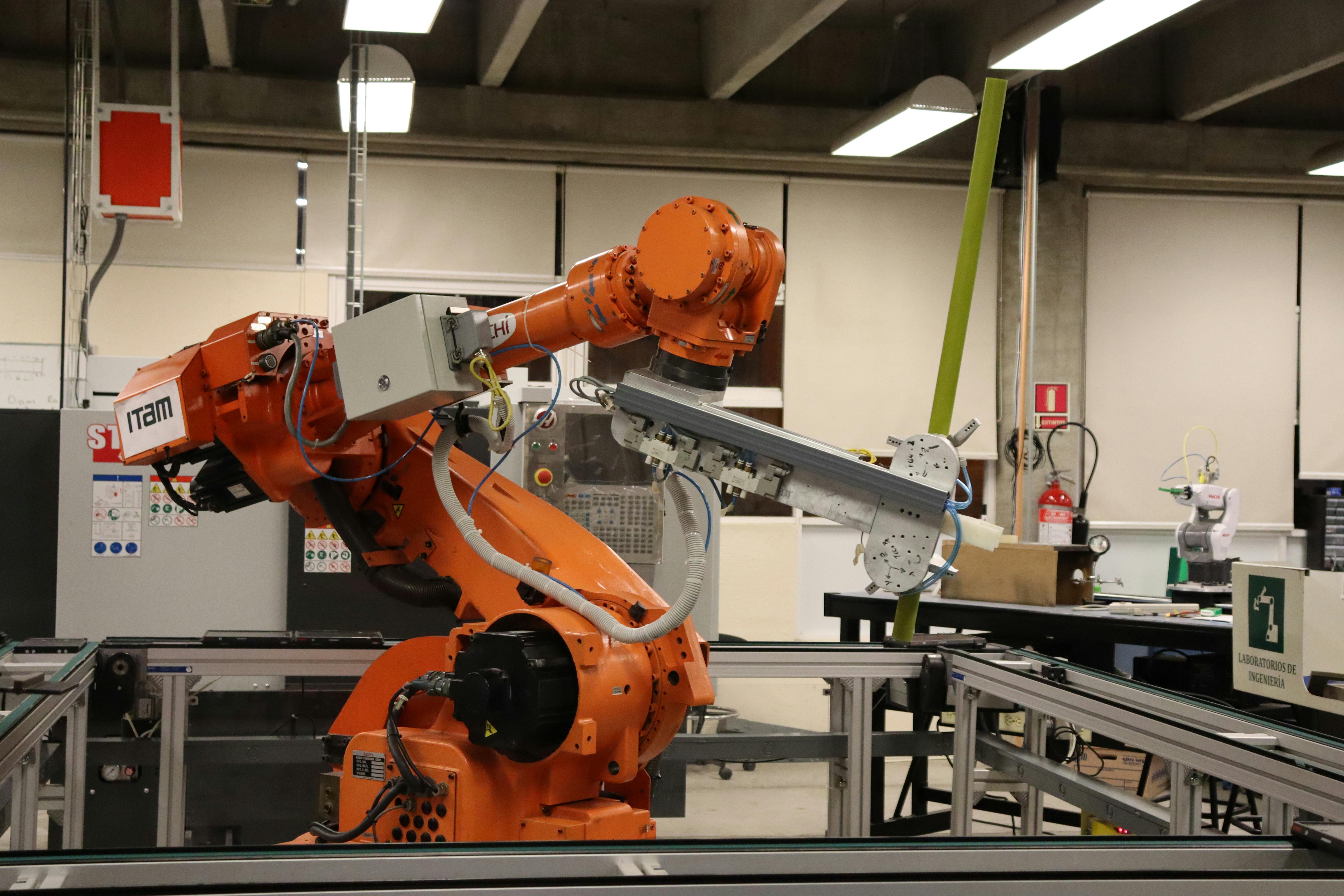

Modern food packaging facilities in the Netherlands generally utilize a combination of manual labor and automated systems. Workers may operate machinery that cleans, sorts, weighs, and packages food products according to specific requirements. The level of automation varies between facilities, with some operations requiring more manual intervention than others, particularly for delicate items or specialty products.

The industry is characterized by strict adherence to schedules and production targets. Efficiency is paramount as many food products have limited shelf lives and must move quickly through the supply chain. Teamwork is essential, with workers often rotating through different stations to maintain productivity and prevent repetitive strain injuries.

Workplace Environment and Conditions in Food Packing

Food packing environments in the Netherlands are typically characterized by controlled temperatures tailored to preserve product quality and safety. Many facilities maintain cool conditions, especially those handling refrigerated or frozen products. Workers should expect to wear appropriate protective gear including hairnets, gloves, and sometimes protective clothing depending on the specific food being processed.

Physical requirements for these positions can be substantial. The work often involves:

-

Standing for extended periods (often 8-hour shifts)

-

Repetitive movements such as lifting, sorting, and packaging

-

Carrying items weighing up to 15-20 kg in some roles

-

Working at a consistent pace to maintain production lines

Shift patterns vary by facility, but many operate with morning, afternoon, and night shifts. Workers may be required to work weekends or holidays depending on production demands and seasonal fluctuations. The industry experiences peak periods, particularly around holidays and during harvest seasons for certain produce, when temporary workers are often brought in to handle increased volumes.

Noise levels in packaging facilities can be significant due to machinery operation, requiring hearing protection in some areas. The working pace can be fast, particularly on assembly lines where products move continuously and require quick handling and decision-making by workers.

Food Processing Standards and Requirements

The Dutch food industry operates under some of the strictest food safety standards in the world. Workers entering this field should be aware of several key requirements and standards:

HACCP (Hazard Analysis Critical Control Points) principles form the foundation of food safety in the Netherlands. Workers typically receive training in basic hygiene practices, contamination prevention, and critical control point monitoring. The Netherlands Food and Consumer Product Safety Authority (NVWA) enforces these standards through regular inspections.

Personal hygiene requirements are particularly stringent. Workers must maintain high standards of cleanliness, including thorough handwashing protocols, proper protective equipment usage, and restrictions on personal items in production areas. Most facilities prohibit jewelry, nail polish, and require covered hair to prevent contamination.

For non-Dutch workers, language requirements vary by facility. While some positions may require basic Dutch communication skills for safety reasons, many facilities employ international workers and may provide materials in multiple languages. English is often used as a common language in more diverse workplaces.

Educational requirements for entry-level positions are typically minimal, with on-the-job training provided. However, specialized roles or supervisory positions may require vocational training in food processing or previous industry experience. The Netherlands offers vocational training programs (MBO) specifically focused on food technology and production.

Employment Considerations for Food Packing Workers

The food packing industry in the Netherlands employs both permanent staff and seasonal or temporary workers. Temporary positions are common during peak production periods, with many workers initially entering the industry through temporary employment agencies. These agencies often specialize in recruiting for the food sector and can provide information about current industry needs.

Compensation varies based on experience, specific role, and company size. Entry-level positions typically start near the Dutch minimum wage, while experienced workers or those in specialized roles may earn more. Most positions provide standard Dutch employment benefits including holiday pay, vacation days, and social insurance contributions.

Career advancement opportunities exist within the industry, with many supervisors and team leaders having started in entry-level positions. Workers who demonstrate reliability, attention to detail, and good communication skills may advance to quality control positions, team leadership roles, or specialized machine operation.

Workers from outside the EU should be aware of work permit requirements. The Netherlands has specific regulations regarding non-EU workers, and most employers require legal authorization to work before considering applications.

Industry Outlook and Developments

The Dutch food packaging industry continues to evolve with technological advancements and changing consumer preferences. Automation is increasingly prevalent, with some facilities investing in robotics and AI-driven quality control systems. This shift is gradually changing workforce needs, with greater emphasis on technical skills and machine operation rather than purely manual tasks.

Sustainability initiatives are becoming central to many Dutch food packaging operations, with companies implementing reduced plastic usage, recyclable materials, and more energy-efficient processes. These changes may create new roles focused on sustainability compliance and innovation.

The industry maintains relatively stable demand throughout economic cycles due to the essential nature of food products. However, like many sectors, it faces challenges including labor shortages in certain regions and adapting to changing regulatory requirements.

This article provides general information about the food packing industry in the Netherlands and does not represent specific job listings or employment opportunities. Those interested in pursuing work in this field should contact employment agencies specializing in food production positions or apply directly to food manufacturing companies operating in the Netherlands.