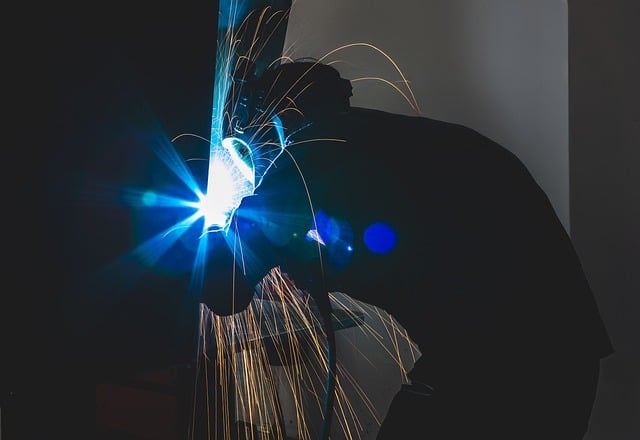

Discover the Work Environment of Welding Jobs Across the UK!

In the United Kingdom, welding offers a range of opportunities for those interested in the field. Working in welding is like engaging with a dynamic and hands-on profession that provides insight into diverse working conditions, particularly in bustling welding fabrication cities. Understanding the specifics of these environments is essential for those considering a career in welding, as it encompasses various industries and settings where metal fabrication is vital.

What are the typical work environments for welders in the UK?

The UK welding industry encompasses several distinct work settings, each with its own characteristics and demands. Manufacturing facilities represent one of the most common environments, where welders typically work indoors on production lines creating components for various industries. These settings often feature controlled conditions with dedicated workstations, specialized equipment, and regular shift patterns.

Construction sites present a contrasting environment, with welders working outdoors or in partially completed structures. These positions frequently involve greater mobility, adapting to changing weather conditions, and collaborating with various trades. Construction welders may need to travel between sites and work at heights or in confined spaces, requiring additional safety certifications and flexible working hours.

Shipyards and offshore platforms constitute another significant sector, particularly in coastal regions like Glasgow, Newcastle, and Portsmouth. These environments involve working with heavy marine-grade materials, often in challenging conditions including exposure to elements and strict safety protocols. Offshore welding positions typically operate on rotation schedules, with workers spending weeks on platforms followed by shore leave periods.

Repair and maintenance workshops represent a fourth common setting, where welders fix damaged equipment and components. These environments tend to involve varied project work rather than production-line repetition, with welders solving unique problems for each item requiring repair.

How do welding fabrication cities impact work opportunities?

The UK’s industrial heritage has created several welding fabrication hubs that continue to influence job availability and specialization opportunities. Sheffield, historically known as the “Steel City,” maintains a significant metalworking presence despite industry contractions. The city hosts numerous fabrication shops specializing in precision components for sectors including aerospace, medical equipment, and specialized machinery. These operations typically offer opportunities for welders skilled in working with specialty steels and high-tolerance specifications.

Birmingham and the West Midlands represent another major fabrication region, with strong ties to automotive and manufacturing industries. Welders in this area often find opportunities working with robotic welding systems, automated production lines, and advanced manufacturing techniques. The concentration of industry creates a network effect that generates related positions in maintenance, repair, and specialized fabrication.

Scotland’s central belt, particularly around Glasgow, maintains significant fabrication capacity connected to energy industries including oil, gas, and renewable infrastructure. These workshops often handle large-scale fabrication projects requiring heavy plate welding and structural components. The region’s connection to offshore industries creates distinctive opportunities for welders willing to pursue additional certifications for marine and energy sector work.

Port cities including Belfast, Liverpool, and Southampton continue to support marine-related fabrication, though at reduced scales compared to historical levels. These locations offer specialized environments for welders interested in shipbuilding, repair, and maritime infrastructure projects.

What are the key metal fabrication cities and their opportunities for welders?

Manchester and its surrounding areas have transformed their traditional heavy industry base but maintain significant metal fabrication activity. The region now features diverse operations ranging from architectural metalwork to precision components for emerging technologies. This variety creates opportunities for welders with different specializations and skill levels, from entry-level positions to highly skilled roles working with exotic materials.

Aberdeen deserves special mention for its connection to North Sea energy infrastructure. The city hosts numerous fabrication companies supporting offshore operations, creating distinctive opportunities for certified welders. These positions often offer premium compensation to reflect the specialized skills required for energy sector compliance and the sometimes challenging work conditions.

Hull has developed a growing fabrication sector connected to renewable energy, particularly supporting offshore wind infrastructure. Welders in this region increasingly find opportunities working on components for turbine foundations, towers, and related structures. This emerging sector seeks welders familiar with working to strict quality standards required for critical infrastructure.

Sunderland and the northeast maintain fabrication traditions connected to both maritime and general industrial applications. The region hosts operations ranging from small specialist fabricators to larger facilities supporting infrastructure projects. These varied settings create entry points for welders at different career stages and with different specializations.

How do indoor versus outdoor welding environments differ in the UK?

The distinction between indoor and outdoor welding environments significantly impacts daily work experiences across the UK. Indoor settings typically provide climate-controlled conditions that enable consistent work regardless of weather. Manufacturing facilities, fabrication shops, and dedicated workshops offer stable environments with permanent equipment setups, controlled ventilation systems, and reliable power supplies. These settings generally allow for more predictable work schedules and consistent output quality.

Outdoor welding environments present different challenges, particularly given the UK’s variable climate. Construction sites, infrastructure projects, and field repairs require welders to adapt to changing conditions including rain, wind, and temperature fluctuations. These positions often involve portable equipment, temporary shelters, and additional precautions to maintain weld quality despite environmental factors. Welders in these settings typically need broader problem-solving skills to adapt standard techniques to non-standard conditions.

Semi-outdoor environments represent a middle ground found in shipyards, large fabrication yards, and partially completed structures. These settings often involve covered work areas that provide some protection from direct weather exposure while still requiring adaptation to temperature variations, air movement, and changing light conditions throughout the year.

What specialized welding environments exist in the UK manufacturing sector?

Beyond the general work settings, several specialized environments offer distinctive opportunities for UK welders. Aerospace manufacturing facilities maintain highly controlled environments with stringent cleanliness standards, specialized equipment, and comprehensive quality control processes. Welders in these settings work with exotic alloys requiring precise temperature control and often utilize advanced techniques including electron beam welding and laser welding.

Food and pharmaceutical equipment fabrication represents another specialized sector requiring welders familiar with sanitary standards and high-finish requirements. These environments typically feature stainless steel fabrication with strict quality control to ensure surfaces meet hygiene regulations for sensitive applications.

Nuclear and defense industries maintain specialized fabrication facilities with rigorous security protocols and exceptional quality standards. Welders in these environments undergo additional background checks and certification processes, working on projects requiring perfect execution and comprehensive documentation.

Automotive and transportation manufacturing presents distinctive environments featuring high levels of automation, robotic welding systems, and assembly line processes. Welders in these settings often work alongside automated systems, performing specialized operations and quality control checks within fast-paced production environments.

Understanding these diverse work environments helps welding professionals identify career paths aligned with their preferences and strengths, whether they favor the consistency of controlled settings or the variety of field-based positions across the United Kingdom’s evolving metal fabrication landscape.