Discovering Food Packing Job Opportunities - London

Those who live in London can delve into the dynamics of working in food packing warehouses. This sector offers a glimpse into the food packaging industry, highlighting the conditions, expectations, and environments found in warehouses. It serves as a vital component of food processing, packaging, and labeling practices across various cities.

Understanding Food Packaging Operations in London

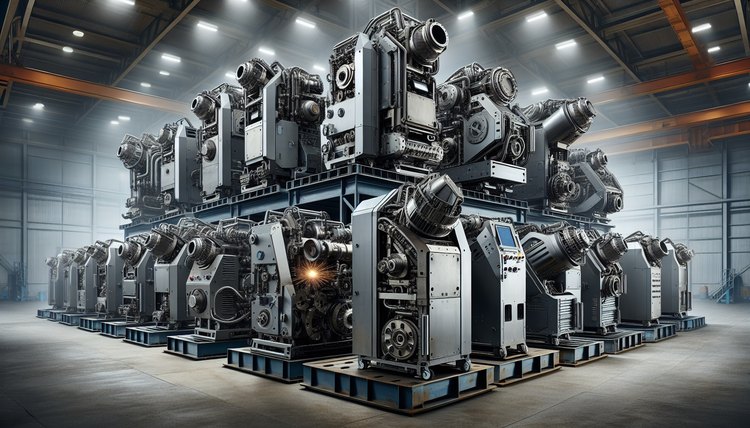

London hosts numerous food manufacturing facilities and distribution centers that rely on efficient packaging operations. Food packaging work typically involves tasks such as sorting food items, operating packaging machinery, quality inspection, and preparing products for shipment. These operations vary widely depending on the specific food sector—whether it’s bakery goods, prepared meals, fresh produce, meat processing, or beverage packaging.

The scale of operations ranges from small artisanal food producers to large industrial facilities that supply major supermarket chains. London’s strategic position as a distribution hub means packaging facilities often operate extended hours, with shifts running throughout the day and night to meet consumer demand and delivery schedules.

Workplace Environment and Conditions

Food packaging environments typically prioritize cleanliness and hygiene due to strict food safety regulations. Workers can expect climate-controlled facilities, which may be kept at cooler temperatures for food preservation purposes. Protective equipment is standard, including hairnets, gloves, aprons, and sometimes ear protection in areas with loud machinery.

The physical demands of food packaging work often include standing for extended periods, repetitive motions, and occasionally lifting moderate weights. Some positions involve working with specialized equipment that requires training and certification. Modern facilities increasingly incorporate ergonomic considerations and automation to reduce physical strain, though the level of technological advancement varies significantly between operations.

Work schedules in food packaging can include shift patterns, weekend work, and seasonal fluctuations based on consumer demand. Larger operations typically run multiple shifts to maintain continuous production, while smaller facilities might operate during standard business hours with occasional overtime during peak periods.

Food Processing Standards and Requirements

The food packaging industry operates under stringent regulatory frameworks designed to ensure product safety and quality. In London, facilities must comply with UK food safety legislation, including the Food Safety Act and regulations established by the Food Standards Agency. Additionally, many operations follow international standards such as Hazard Analysis Critical Control Point (HACCP) protocols and may hold certifications like BRC (British Retail Consortium) Global Standard for Food Safety.

For individuals seeking work in food packaging, employers typically require:

-

Food hygiene awareness or certification (with training often provided)

-

Understanding of health and safety procedures

-

Reliability and punctuality

-

Attention to detail for quality control purposes

-

Ability to work in team environments

-

Physical stamina for standing and repetitive tasks

Many positions do not require previous experience or advanced qualifications, making the sector accessible as an entry-point to the workforce or for those seeking flexible employment. However, supervisory or technical roles may require relevant experience or qualifications in food technology, manufacturing, or related fields.

Career Progression in Food Packaging

The food packaging sector offers various advancement paths for motivated individuals. Entry-level positions in packaging operations can lead to roles such as team leader, shift supervisor, quality control specialist, or even production management with appropriate experience and training.

Skills developed in food packaging work—such as understanding supply chain logistics, food safety protocols, and production efficiency—are transferable across the broader food manufacturing industry. Some workers use their experience as a foundation for further specialized training in food technology, quality assurance, or operations management.

Larger companies often provide internal training programs and apprenticeships that allow employees to develop technical skills related to specific machinery or processes. These opportunities can lead to specialization in areas like machine operation, maintenance, or quality inspection.

Finding Food Packaging Opportunities

Information about food packaging work can be found through various channels. Employment agencies specializing in industrial, manufacturing, or food sector recruitment often list temporary and permanent positions. Local job centers and online job platforms frequently feature entry-level packaging roles with minimal qualification requirements.

For those interested in developing a career in this sector, industry-specific resources such as food manufacturing associations and training providers offer guidance on skills development and certification options. Vocational courses in food processing, manufacturing, or logistics can provide relevant background knowledge that enhances employment prospects.

It’s worth noting that many facilities hire based on seasonal demand, particularly those handling fresh produce or preparing holiday-specific products. These temporary positions sometimes transition to permanent roles for reliable workers, making them a potential entry point to the industry.

Industry Outlook and Considerations

The food packaging sector demonstrates relative stability due to consistent consumer demand for packaged foods. However, like many industries, it faces ongoing changes driven by automation, sustainability concerns, and evolving consumer preferences. Workers entering the field should be prepared for an environment where adaptability and willingness to learn new technologies are increasingly valuable.

The industry’s move toward more sustainable packaging solutions is creating new roles focused on environmental compliance and innovation. Similarly, increased automation is shifting some positions toward machine operation and monitoring rather than manual packaging tasks.

Food packaging work offers accessible employment opportunities with clear progression paths for those willing to develop industry-specific knowledge. While the work can be physically demanding and routine, it provides stable employment in an essential industry that continues to evolve with technological and environmental changes.