Explore Food Packing Job Environments in Edmonton's Warehouses for English Speakers

For individuals residing in Edmonton who are fluent in English, food packing jobs offer a unique insight into warehouse operations. These positions involve various tasks crucial to the food supply chain, ranging from sorting to packaging. Understanding the working conditions and requirements can help in deciding if this career path aligns with personal goals and interests.

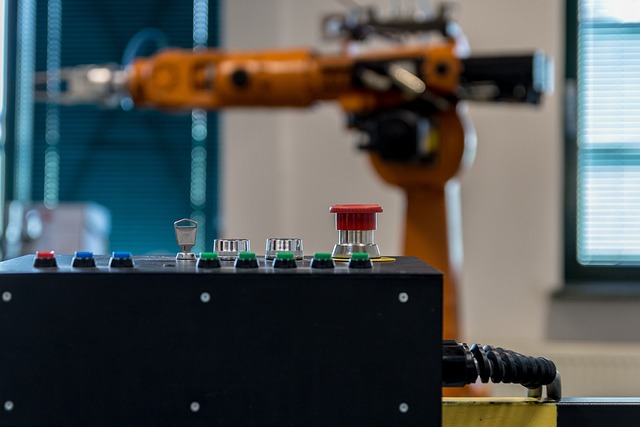

Food packing operations in Edmonton represent a significant component of the city’s manufacturing and warehouse sector. These work environments involve handling various food products, from fresh produce to processed goods, requiring attention to detail and adherence to strict safety protocols. Understanding these operations provides insights into Alberta’s food processing industry and warehouse management practices.

Understanding the Responsibilities of Food Packing Roles

Food packing roles typically encompass a range of duties that vary depending on the specific facility and product type. These positions generally involve handling packaging materials, operating basic machinery, and ensuring products meet quality standards before shipment. Common tasks include sorting items by size or type, placing products into containers or bags, applying labels, and conducting visual inspections for defects or contamination.

Workers in these roles must follow detailed procedures for handling different food categories, maintaining proper hygiene standards, and documenting production quantities. Many positions involve standing for extended periods, lifting packages weighing up to 50 pounds, and working efficiently to meet production targets. Training programs typically cover food safety regulations, equipment operation, and workplace safety protocols specific to each facility type.

Working Conditions in Edmonton’s Food Packing Warehouses

Edmonton’s food packing facilities operate in various environments designed to maintain product integrity and worker safety. Many warehouses feature climate-controlled areas with temperatures ranging from refrigerated zones for perishables to ambient conditions for dry goods. Proper ventilation systems ensure air quality standards while specialized flooring provides slip resistance in wet areas.

Shift patterns in these facilities often include day, evening, and overnight operations to accommodate continuous production demands. Some facilities operate on rotating schedules, providing various working arrangements. Safety equipment such as hairnets, gloves, and protective footwear is typically provided, while ergonomic workstations help reduce physical strain during repetitive tasks.

Noise levels vary by facility type, with some requiring hearing protection in areas with heavy machinery. Break rooms and cafeterias provide spaces for rest periods, and facilities may include various amenities and safety features designed to support worker wellbeing.

Skills and Qualifications for Successful Food Packing Jobs

Successful performance in food packing roles requires a combination of physical capabilities and attention to detail that ensures efficient operations. Basic math skills help with counting and measuring products, while good hand-eye coordination assists with precise packaging tasks. The ability to follow written and verbal instructions in English is essential for understanding safety protocols and production requirements.

Physical stamina enables workers to maintain productivity during full shifts, while teamwork skills facilitate smooth operations in collaborative environments. Many positions require minimal formal education, making them accessible entry points into the manufacturing sector. Previous warehouse experience can be beneficial but comprehensive training programs typically prepare workers for their roles.

Reliable attendance and punctuality are highly valued qualities in these environments, as production schedules depend on consistent operations. Workers who demonstrate initiative and willingness to learn additional skills often find advancement opportunities within organizations. Basic computer literacy may be required for facilities using digital tracking systems or automated packaging equipment.

| Company Type | Facility Focus | Typical Requirements |

|---|---|---|

| Meat Processing | Production Operations | High school diploma, physical fitness |

| Food Distribution | Warehouse Operations | Forklift certification preferred |

| Bakery Operations | Packaging Systems | Food safety training, teamwork skills |

| Retail Distribution | Order Processing | Basic math skills, attention to detail |

Edmonton’s food packing industry continues to evolve with technological advances and changing consumer demands. Automation has introduced new equipment that requires workers to adapt their skills while maintaining the human oversight necessary for quality control. Career progression paths exist within these operations, with potential advancement to supervisory roles, quality assurance positions, or specialized equipment operation.

The sector’s characteristics make it an important component of Edmonton’s manufacturing landscape. The city’s strategic location and transportation infrastructure support food processing facilities, creating ongoing demand for skilled packaging operations. Understanding the responsibilities, working conditions, and required qualifications helps individuals learn about this essential industry sector and its role in the broader supply chain.