Exploring Food Packing Roles in Paris for English Speakers

Individuals residing in Paris and proficient in English may consider the experience of working in food packing warehouses. This sector often provides insight into the logistics and operations behind food distribution. The working conditions in these environments can vary, but typically include a focus on efficiency, teamwork, and adherence to safety protocols. Understanding the dynamics of food packing can offer valuable knowledge for those interested in the industry.

Food packing roles form an integral part of Paris’s food processing industry, spanning diverse sectors from artisanal food preparation to large-scale manufacturing operations. These positions exist within various facility types throughout the Paris region, each with distinct operational characteristics and workplace environments.

The food processing sector in Paris encompasses bakery operations, dairy processing facilities, meat preparation plants, and packaged goods manufacturing. International companies often maintain operations in the region, creating multilingual work environments where English proficiency can be beneficial for communication and documentation purposes.

Understanding the Work Environment in Paris Food Packing Warehouses

Food packing facilities in Paris typically maintain controlled environments designed to preserve product quality and meet safety regulations. These workplaces feature temperature-controlled areas, specialized ventilation systems, and strict hygiene protocols to ensure food safety standards.

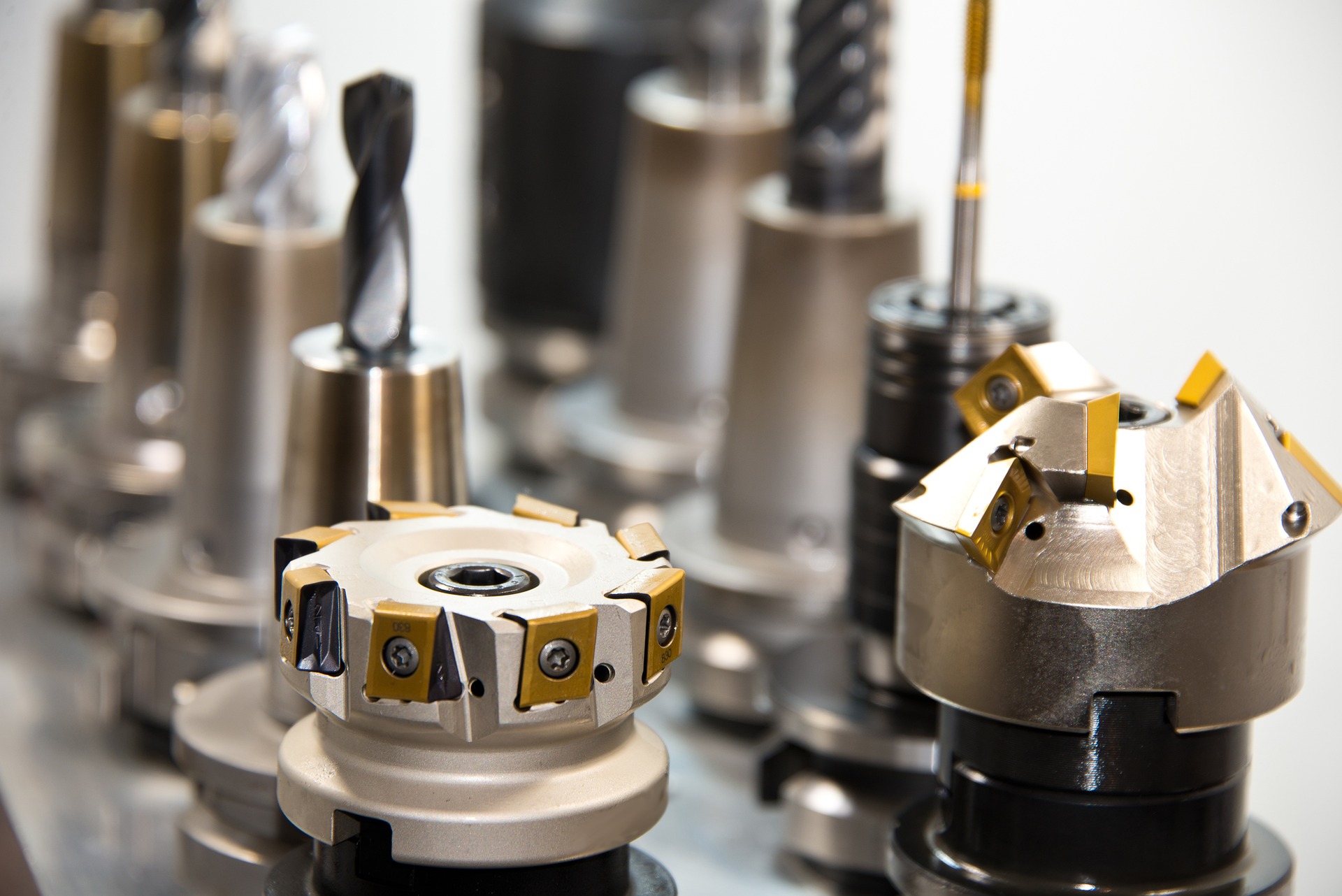

Modern packaging equipment, conveyor systems, and automated sorting mechanisms characterize most facilities. Workers operate within structured safety frameworks, following comprehensive protocols for proper handling techniques, hygiene maintenance, and emergency procedures. Standard protective equipment includes gloves, hairnets, and safety footwear.

Facility layouts vary from compact urban operations to expansive suburban complexes. Work activities typically involve extended standing periods, with tasks requiring moderate physical engagement including lifting, sorting, and machinery operation. Shift patterns often accommodate various scheduling preferences, with some facilities operating around-the-clock production cycles.

Key Responsibilities in Food Packing Positions in Paris

Food packing roles encompass several core responsibilities centered on product preparation, quality assessment, and packaging operations. Workers engage in sorting incoming products, verifying expiration dates, and ensuring items meet established quality criteria before packaging processes begin.

Packaging operations involve various machinery types, from manual sealing equipment to sophisticated automated systems. Responsibilities include maintaining accurate production records, applying correct labeling, and organizing finished products for distribution channels. Many positions incorporate basic computer usage for inventory management and production tracking.

Quality control represents a fundamental aspect of food packing work. This involves conducting visual inspections, verifying weight specifications, and identifying potential quality issues. Documentation requirements typically include recording batch information, production timestamps, and quality assessment results.

Collaborative work forms an essential component of food packing operations. Workers coordinate with supervisory staff, maintenance personnel, and quality assurance teams to maintain production efficiency and address operational challenges as they arise.

Skills and Qualifications for Working in Food Packing Roles

Food packing positions generally require minimal formal educational credentials, with most training provided through workplace programs. However, specific skills and attributes significantly influence performance and advancement potential within these roles.

Physical capabilities remain primary requirements, including sustained standing ability, lifting capacity for objects up to 25 kilograms, and coordination for repetitive tasks. Manual dexterity and attention to detail prove essential for quality control and packaging precision.

French language skills, while varying in importance across different facilities, can enhance workplace integration and communication effectiveness. Some organizations provide language development programs to support multilingual workforce needs.

Previous experience in manufacturing environments, warehouse operations, or food service sectors demonstrates relevant transferable capabilities. Knowledge of food safety principles, including HACCP standards, can be advantageous for specialized positions and advancement opportunities.

Reliability and schedule flexibility represent valued characteristics in food packing operations, where production continuity depends on consistent staffing patterns. Adaptability regarding shift assignments and overtime requirements often correlates with expanded role opportunities.

Food safety certifications, while not universally mandated, can distinguish candidates and qualify individuals for enhanced responsibility levels. Some employers facilitate certification acquisition through workplace training initiatives.

Food packing roles within Paris’s industrial sector provide insight into France’s food processing industry, offering perspectives on workplace environments, operational requirements, and skill development pathways within this manufacturing segment.