Insights into Food Packing Careers Available Across Latvia

Individuals residing in Latvia may find valuable opportunities in the food packaging sector. This industry offers insights into career flexibility and evolving income trends. With a focus on job security and potential growth, understanding the landscape of food packing roles can aid in making informed career decisions.

The food packaging industry constitutes a significant segment within Latvia’s broader manufacturing sector. From dairy products to prepared meals, various food items require careful handling and packaging before reaching consumers. This article explores the general landscape of food packing work in Latvia, examining the nature of these positions, typical workplace environments, and the overall structure of this industry segment. By understanding the characteristics of food packing work, readers can gain insights into this particular aspect of Latvia’s industrial economy.

Understanding the Food Packaging Industry in Latvia

Latvia’s food packaging industry operates within the country’s broader food processing sector. The industry encompasses various subsectors, including dairy product packaging, meat processing, fish preservation, fruit and vegetable processing, and bakery goods packaging. Food packaging facilities exist in different regions across Latvia, with concentrations near agricultural production areas and transportation hubs. Both domestic and international companies maintain packaging operations throughout the country.

The sector functions according to European Union food safety regulations, requiring adherence to hygiene protocols and quality standards. Most facilities operate year-round, though seasonal variations occur in sectors tied to agricultural harvests, such as fruit and vegetable processing. The industry contributes to Latvia’s economy through both domestic distribution and export activities, with packaged goods reaching markets throughout the Baltic region and beyond.

Exploring Income Trends for Food Packing Positions

Compensation within the food packaging sector in Latvia varies based on several factors including experience, specific responsibilities, location, and employer size. The industry generally follows Latvia’s national wage structures, with variations based on the complexity of tasks performed. Positions requiring specialized skills or technical knowledge typically command different compensation than entry-level roles.

Factors that may influence compensation include shift schedules, as many facilities operate beyond standard business hours. Geographic location also plays a role, with regional economic differences affecting wage structures throughout the country. Some positions may include additional elements beyond base compensation, such as performance metrics or quality standards achievements.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The Flexibility of Food Packing Careers in Latvia

The food packaging industry in Latvia demonstrates certain structural characteristics regarding scheduling and skill requirements. Many facilities operate multiple shifts to maintain production continuity, resulting in various schedule configurations. This operational necessity creates a work environment with different timing options within the industry as a whole.

The sector encompasses positions with varying skill requirements, from roles focused on basic packaging tasks to those involving machine operation or quality control. This range of position types contributes to the industry’s overall structure. The food packaging sector generally maintains consistent operational patterns throughout the year, though some subsectors experience seasonal fluctuations based on agricultural production cycles or consumer demand patterns.

Skills Relevant to Food Packaging Work

Food packaging work typically involves several core competencies that apply across different facility types. Attention to detail represents an important quality, as workers must ensure products meet quality and safety standards. Understanding of basic food handling procedures and sanitation protocols is generally necessary, as these facilities operate under strict hygiene requirements to maintain food safety.

Depending on the specific role, relevant skills might include machine operation, quality assessment, or knowledge of packaging materials and techniques. Physical stamina often proves important, as many positions involve standing for extended periods and performing repetitive motions. Communication abilities can be valuable for coordinating with team members, especially in fast-paced production environments where efficiency depends on clear information exchange.

Working Environments in Food Packaging Facilities

The physical environments in food packaging facilities share certain common characteristics while varying based on the specific food products being processed. Temperature control represents a consistent feature, with facilities maintaining appropriate conditions for food safety—potentially resulting in cool environments for meat and dairy processing or warmer settings for bakery operations. Noise levels vary by facility type, with more mechanized operations generally producing higher ambient sound.

Personal protective equipment such as hairnets, gloves, and specialized clothing typically constitutes a standard requirement across facilities. Modern operations increasingly incorporate ergonomic considerations in workspace design, though the nature of packaging work remains physically active. Facilities must maintain strict cleanliness standards in accordance with food safety regulations, resulting in regular cleaning protocols and sanitized work environments.

Industry Developments and Technological Changes

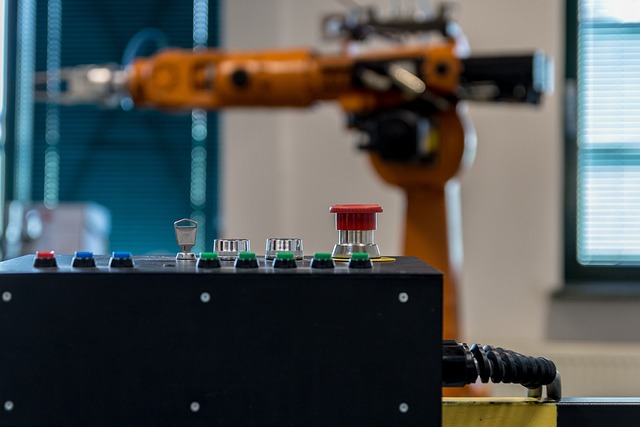

The food packaging sector in Latvia continues to evolve alongside technological advancements, changing consumer preferences, and sustainability concerns. Automation increasingly influences certain aspects of the industry, with technology handling some tasks previously performed manually. This technological shift affects the nature of work within the sector, potentially emphasizing different skill sets than in previous decades.

Growing consumer interest in sustainable packaging has prompted innovation in materials and processes throughout the industry. Latvia’s position within the European Union means its food packaging sector operates within broader European market trends and regulatory frameworks. These factors collectively shape the industry’s development trajectory, influencing everything from production methods to quality control processes. Understanding these trends provides context for how this sector fits within Latvia’s broader economic landscape and its potential future directions.