Insights into Food Packing Jobs for English Speakers in Dessau

Individuals residing in Dessau who are proficient in English may gain insights into the work involved in food packing warehouses. This environment typically requires attention to detail and adherence to safety protocols to ensure the quality and safety of food products. The experience in these settings can provide valuable knowledge about warehouse operations, teamwork dynamics, and the importance of efficient processes.

Food production and distribution rely on careful handling, accurate labeling, and consistent hygiene. In Dessau, warehouse and factory operations follow structured processes to protect product quality and consumer safety. English speakers can contribute effectively in these settings by understanding how the workflow is organized, what the role covers, and which on-site rules matter most for smooth operations.

Food packing jobs for English speakers in Dessau

For English speakers, daily tasks are typically practical and well-structured, guided by supervisors, checklists, and illustrated work instructions. Many teams use color-coding, symbols, scanners, and standardized procedures to support clarity. While not every site operates in English, simple phrases in German can help with briefings, break schedules, and health and safety notices. Insights into Food Packing Jobs for English Speakers in Dessau often center on understanding key routines: clocking in, collecting personal protective equipment, reviewing task boards, and maintaining hygiene before entering production zones.

Shift patterns may vary across facilities, including early, late, night, or rotating shifts. Workflows often involve standing for extended periods, repetitive movements, and coordination with upstream pickers or downstream dispatch teams. Clear communication is valued, but clarity of process usually matters even more: if you can follow instructions, maintain pace, and record your work correctly, you can integrate well with teams even as your language skills develop. Local services in your area sometimes provide short induction sessions to explain site rules and highlight key contacts.

Role of food packing in Dessau warehouses

Food packing sits at the core of getting products shelf-ready. Tasks typically include assembling packaging, weighing portions, sealing and labeling items, adding lot codes and dates, and preparing boxes for palletizing. In fresh or chilled lines, temperature checks and quick movement reduce time out of refrigeration. In dry goods, batch accuracy and label consistency dominate. Understanding the Role of Food Packing in Dessau Warehouses also means tracing items: scanning barcodes, logging quantities, and noting any defects so issues can be contained and investigated.

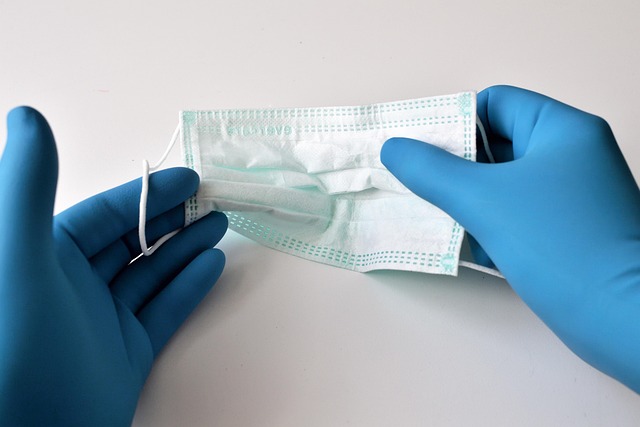

Hygiene and quality frameworks guide the work. Facilities commonly use HACCP-based procedures and site-specific rules for allergen separation, handwashing, and tool sanitation. Workers use hairnets, gloves, and protective coats; jewelry and loose items are restricted to prevent contamination. Ergonomic practices—lifting with correct posture, rotating tasks when possible, and using aids like trolleys—reduce strain. These steps keep operations efficient while supporting product integrity and worker well-being.

Key considerations for food packing work

Key Considerations for Working in Food Packing Environments include safety, cleanliness, and documentation. Safety covers manual handling, awareness around conveyors, and careful use of cutting tools. Cleanliness involves regular hand hygiene, changing PPE as required, and following entry rules for high-care zones. Documentation includes completing checklists, confirming counts, and recording any anomalies promptly so supervisors can act.

Dress codes are strict in production areas: closed-toe shoes, hair protection, and clean workwear are typical. Some sites are cold, so layering beneath protective coats can help. Ear protection may be needed near noisy machinery. Reliability matters: arriving on time, reporting issues early, and staying consistent with counts and labels help the whole line stay on schedule. For English speakers, visual aids, standardized symbols, and handheld scanners can make instructions easier to follow, while brief German phrases assist with shift updates and safety announcements.

Administrative basics support a smoother start. Having the right to work in Germany, registering your address when required, and holding health insurance are standard expectations. Many facilities provide short trainings on hygiene rules, allergen control, and equipment use. A willingness to learn site terminology—product codes, station names, and quality flags—helps you adapt quickly. With steady attention to detail and a respectful approach to shared spaces, you can navigate food packing roles confidently in Dessau’s warehouse and production environments.

Practical tips for day-to-day success

Prepare for time on your feet by choosing comfortable, supportive footwear that meets site rules. Stay hydrated within scheduled break times and pace your movements to keep accuracy high. Use checklists to track steps—assemble, fill, seal, label, and verify—so nothing is missed. If something seems off, pausing to confirm with a supervisor prevents larger rework later. Keep personal items stored properly, and maintain a tidy station to reduce mix-ups and speed line changes.

Finally, keep communication simple and factual. When a count changes, a label jams, or a seal looks weak, a short, clear note helps the team act quickly. Over time, familiarity with products, common exceptions, and routine quality checks will make each shift feel more predictable. For English speakers building experience in your area, a grounded understanding of workflows and hygiene rules is the foundation for dependable, consistent performance in food packing roles.

Conclusion

Food packing in Dessau is structured around hygiene, accuracy, and reliable teamwork. English speakers can succeed by focusing on clear routines, learning essential site terms, and following safety procedures closely. With consistent attention to detail, these environments offer a stable, process-driven path to contribute to food quality and supply reliability.