Insights into Food Packing Jobs in Thuringia

Individuals who live in Thuringia and speak English may find interest in the dynamics of food packing warehouses. This sector offers a glimpse into the operational processes involved in food production. Understanding the working conditions and environment can provide valuable context for those considering roles in food packaging.

Thuringia, a state in central Germany, has a food production sector where packing operations form part of the manufacturing process. This article explores the general characteristics of food packing work as a category of industrial employment, without reference to current job openings or hiring trends. The information presented reflects the typical structure of such work environments, though actual conditions vary significantly between facilities and may change over time as industry practices evolve.

Understanding Food Packing Warehouse Environments in Thuringia

Food packing warehouse settings in Thuringia generally operate under hygiene protocols and regulatory standards. These facilities are typically designed to maintain food safety while facilitating production processes. Such environments may range from temperature-controlled spaces to refrigerated areas depending on the products being handled, though specific conditions vary by facility.

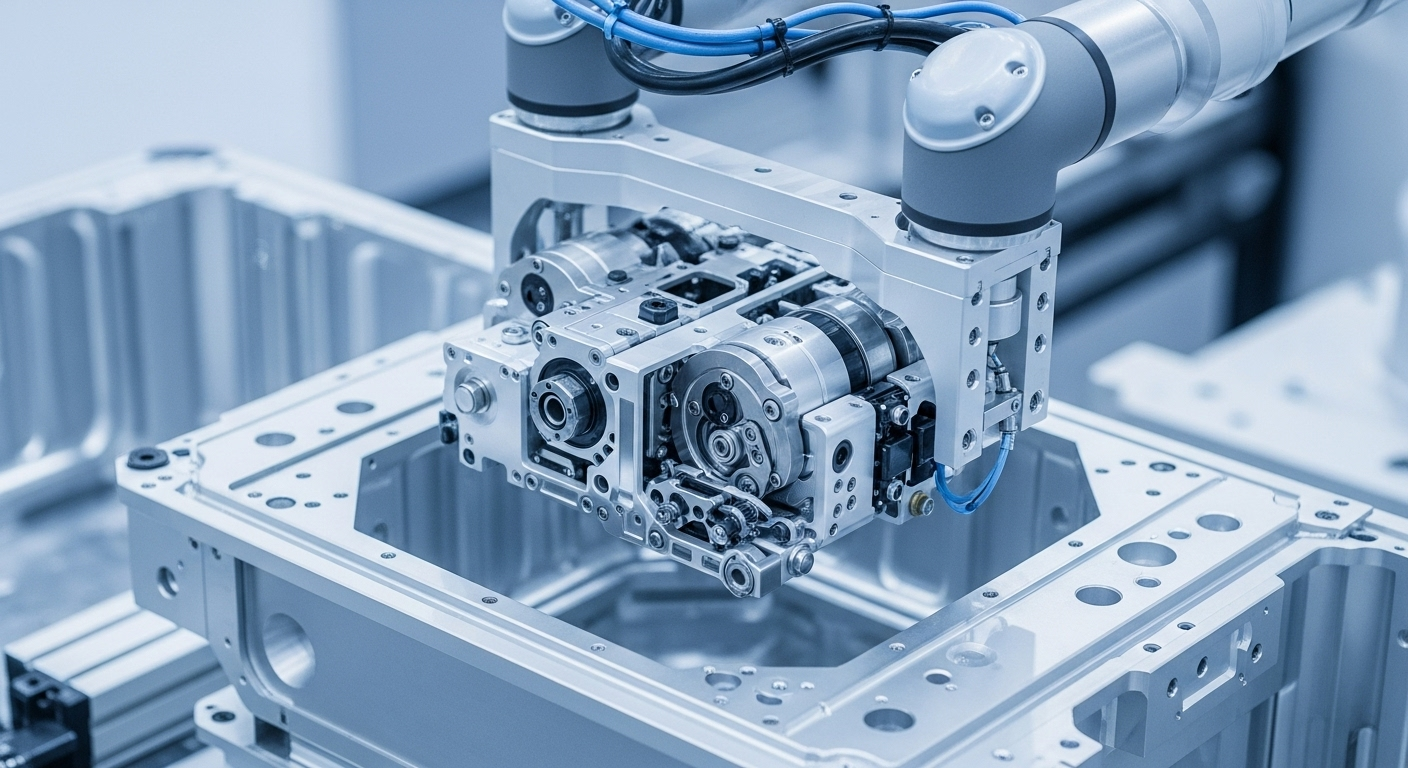

The physical layout of such warehouses commonly includes designated areas for different stages of the packing process. Personal protective equipment (PPE) such as hairnets and gloves represents a standard feature in maintaining hygiene standards. While some facilities incorporate automation technologies alongside manual processes, the exact balance between mechanized and human operations differs substantially between companies and continues to evolve with technological advancements.

Insights into the Nature of Food Packaging Employment

Food packaging work as a category generally encompasses several function types with distinct responsibilities. Tasks might include manual packaging operations, equipment operation, quality assessment, or coordination activities, though specific role definitions and responsibilities vary between employers and facilities.

Work schedules in this sector often involve shift patterns, as many food production facilities operate extended hours. The pace and intensity of work typically relates to production requirements and can involve repetitive tasks requiring attention to detail. Seasonal variations in production volume represent a common feature in some segments of food manufacturing, though their impact on workforce needs varies considerably between product categories and individual companies.

Key Considerations for Those Interested in Warehouse Packing Jobs

The physical nature of food packing work generally involves standing for extended periods, performing repetitive motions, and sometimes handling materials of varying weights. These physical aspects represent important considerations for anyone researching this type of work.

Educational requirements for entry-level positions in this field typically focus on practical capabilities rather than formal qualifications, with most training provided on-site. Language proficiency requirements vary between facilities, with communication needs depending on workplace practices and safety protocols. Understanding these general characteristics helps provide context, though specific requirements differ between employers.

Transportation logistics represent another consideration, as industrial facilities may be located in areas with varying levels of public transportation access. The significance of this factor depends entirely on individual circumstances and the specific location of any given facility.

Regulatory Standards and Safety in Food Packing Facilities

Food packing operations in Thuringia generally operate under German and European Union regulatory frameworks. These regulations establish standards for food safety and quality while addressing worker health considerations. The HACCP (Hazard Analysis Critical Control Points) system represents a common approach to food safety protocols in such environments.

Occupational safety measures typically include safety training, equipment usage protocols, and emergency procedures, though specific implementations vary between facilities. Training on ergonomic practices and proper lifting techniques represents a common feature in addressing workplace injury prevention.

Health certificates (Gesundheitszeugnis) are generally required for workers handling food products in Germany, involving medical examinations to verify absence of communicable diseases that could compromise food safety. This requirement reflects the industry’s food safety obligations rather than employment availability.

Compensation and Industry Structure

The food packing sector generally operates within Germany’s labor framework, including minimum wage standards and shift differentials for non-standard working hours. Many facilities operate under collective bargaining agreements (Tarifverträge) that establish standardized conditions, though participation in such agreements varies between companies.

The structure of the industry typically includes various position types from basic operations to specialized functions such as quality assessment or technical maintenance. Larger manufacturing operations may have more defined organizational structures than smaller facilities, affecting the nature of work experiences within different contexts.

Standard German social security provisions including health insurance and pension contributions apply to regular employment in this sector, as in other industries. Additional benefits vary significantly between employers and should not be assumed to be uniform across the industry.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Work Environment Characteristics in Food Production Settings

Work environments in food production facilities often feature diverse teams with varying backgrounds. The effectiveness of operations typically depends on coordination between workers maintaining consistent processes and communication, though specific workplace dynamics vary considerably between facilities.

The social aspects of such work environments differ significantly between companies, influenced by management approaches, facility size, and organizational culture. These variations make generalizations about workplace experience difficult, as individual experiences may differ substantially between settings.

For those unfamiliar with German workplace norms, understanding general expectations regarding punctuality, communication practices, and organizational structures provides helpful context. However, specific workplace cultures vary significantly between companies, with larger organizations sometimes offering more formalized orientation than smaller operations.

Food packing represents one category within Thuringia’s industrial landscape, with characteristics that distinguish it from other types of manufacturing work. While physically demanding and often involving repetitive tasks, the specific nature of such work varies considerably between facilities. This article provides general information about the category of work rather than current employment opportunities, as job availability fluctuates with economic conditions and individual company circumstances. Those interested in specific employment opportunities would need to research current openings through appropriate channels, as this overview cannot address the constantly changing employment market.