Learn about food packaging in Frankfurt am Main for English-speaking professionals

Individuals residing in Frankfurt am Main who are proficient in English may consider gaining insight into the functioning of food packing warehouses. This sector offers a look into the working conditions and daily operations essential for food distribution, providing valuable context for those interested in this field.

Food packaging is an industrial activity that exists within food processing and distribution systems. In cities like Frankfurt am Main, such operations form part of the broader logistics infrastructure. This article provides general educational information about what food packaging work typically involves, without implying the existence of specific positions or hiring activity.

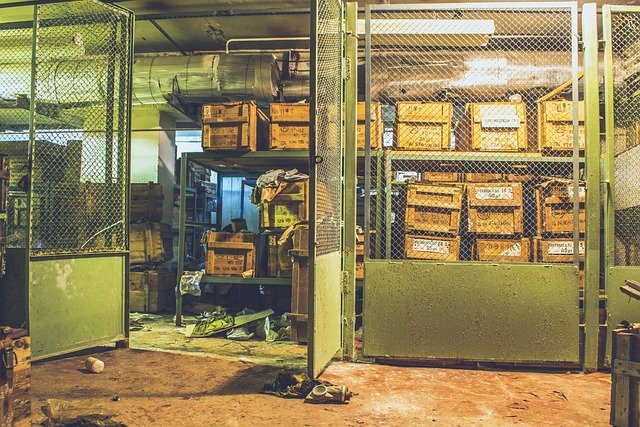

Understanding the work environment in food packing warehouses

Food packing facilities are generally designed as climate-controlled spaces that adhere to food safety standards. Such environments typically require strict hygiene protocols aligned with German and European Union regulations. Workers in these settings usually wear protective clothing, including hairnets, gloves, and specialized footwear. Operations in such facilities may run across multiple shifts to maintain production schedules.

The physical characteristics of these environments often include standing work surfaces, conveyor systems, and packaging machinery. Temperature varies based on product requirements, with certain areas kept cooler for perishable items. Floors are typically concrete, and noise levels depend on the machinery in use. Safety training in such settings generally covers lifting techniques, emergency procedures, and equipment handling protocols.

These facilities typically emphasize teamwork and operational efficiency. The work pace can vary depending on production schedules and seasonal demands. German labor laws regulate break schedules and working conditions in such industrial settings.

Key responsibilities associated with food packing roles

Food packing work generally involves several categories of tasks related to product preparation and packaging. Common activities include sorting food products, conducting quality inspections, and identifying items that do not meet standards. Packaging activities may involve manual placement of items into containers or operation of semi-automated equipment.

Labeling represents another typical component, involving the application of product information, dates, and identification codes to packages. This supports supply chain traceability and regulatory compliance. Weight verification and proper sealing of containers are also standard aspects of such work.

Additional activities may include organizing finished products for storage or shipment, maintaining workspace cleanliness, and performing quality assessments during the packaging process. Some roles involve equipment operation such as forklifts or pallet jacks, which typically requires specific certification. Standard Operating Procedures guide these activities, and reporting mechanisms exist for equipment issues or quality concerns.

Documentation has become an integral part of modern packaging operations. This may involve completing production records, tracking batch information, and monitoring inventory through various systems. Task flexibility is common, with workers potentially assigned to different stations based on operational requirements.

Language requirements for working in Frankfurt’s food industry

Language requirements in food packing environments vary significantly based on employer policies, role specifications, and workforce composition. German language proficiency is generally valued in German workplaces, though the specific level required differs across facilities. Some international operations employ multilingual staff where multiple languages may be used for communication.

For entry-level positions in such environments, language requirements range widely. Some facilities may accommodate workers with limited German skills, while others require functional proficiency. Safety materials and training content availability in multiple languages varies by employer. Basic German understanding related to safety, instructions, and workplace interaction is typically beneficial.

Positions involving supervision or quality control generally require stronger German language skills due to communication needs with management, documentation responsibilities, and interactions with German-speaking personnel and officials. Individuals interested in such roles should consider German language education, which is accessible through various programs in Frankfurt.

The ability to comprehend written German instructions relates to following specifications, standards, and safety protocols. Familiarity with German terminology in food safety and packaging contexts develops through experience. Workplace exposure can contribute to language skill development over time.

General characteristics of industrial food packaging work

Industrial food packaging work in Germany operates within the framework of German employment law, which establishes various worker protections. Standard working hours in industrial settings typically range from 35 to 40 hours weekly, with overtime occurring based on production needs. Employment arrangements may take various forms including temporary, seasonal, or permanent contracts.

Such work involves physical demands including prolonged standing, bending, lifting objects of varying weights, and repetitive task performance. German regulations mandate appropriate break periods and enforce occupational health and safety standards. Industrial facilities typically provide amenities such as break areas, storage lockers, and meal options.

Industrial packaging environments value attributes such as reliability, attention to detail, and collaborative work capability. Punctuality is emphasized due to production line staffing requirements. Demonstration of consistency, quality awareness, and learning orientation may relate to responsibility progression within organizations.

Frankfurt’s role in European logistics means industrial operations exist within the city’s economic structure. Seasonal patterns affect activity levels, with variations during holiday periods and harvest seasons for certain products. Understanding these patterns provides context for how such operations function throughout the year.

Food packaging work represents one category of industrial employment that involves physical labor in structured environments with specific safety and quality standards. Such roles require adaptability, commitment to established protocols, and capability to function in demanding physical conditions. This article provides general educational information about the nature of such work and does not suggest or imply the availability of specific positions, hiring activity, or employment opportunities in Frankfurt am Main or elsewhere.