Portable laser welders improve accuracy and efficiency in Johannesburg

In Johannesburg, portable laser welders are transforming the welding landscape, improving accuracy, saving time, and reducing costs. This technology is particularly beneficial in several sectors, including manufacturing and construction. A closer look at the different models, pricing structures, and practical applications reveals their growing importance in welding manufacturing processes. Furthermore, effective welding training for workers is essential to maximize the potential of these advanced machines.

Johannesburg’s diverse industrial sectors are increasingly recognizing the value of advanced manufacturing and repair techniques. As businesses strive for greater efficiency and higher quality output, the adoption of specialized equipment becomes crucial. Portable laser welders are emerging as a key technology in this shift, offering a powerful combination of precision, speed, and adaptability that can address complex welding challenges across various applications.

Understanding Portable Laser Welding Technology

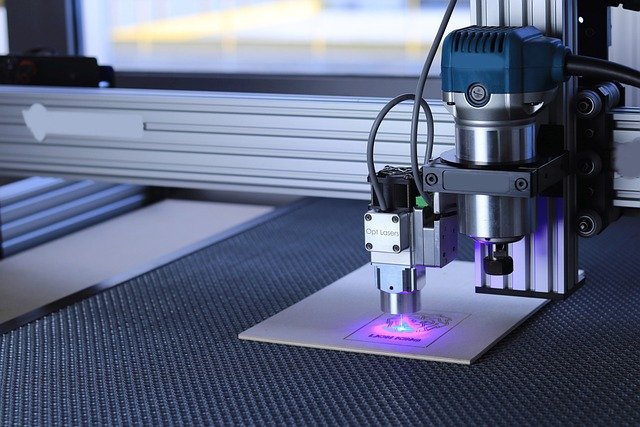

Portable laser welding machines utilize a focused beam of light to create high-strength, low-distortion welds. Unlike conventional welding methods that rely on an electric arc or flame, laser welding concentrates energy into a very small area, resulting in minimal heat input to the surrounding material. This precision allows for extremely fine welds, often with reduced material distortion and a smaller heat-affected zone. The portability aspect means these machines can be easily moved to different job sites or workstations within a facility, offering unparalleled flexibility for on-site repairs, intricate assembly work, and rapid prototyping.

These systems typically consist of a laser source, a fiber optic cable to deliver the laser beam, and a handheld welding head. Operators can precisely control parameters such as power, pulse duration, and spot size, adapting the process to a wide range of materials including stainless steel, aluminum, titanium, and various alloys. The non-contact nature of the process also minimizes tool wear and contamination, contributing to cleaner welds and reduced post-processing requirements.

Benefits of Portable Laser Welding in Johannesburg’s Industrial Sector

For industries in Johannesburg, adopting portable laser welding brings several distinct advantages. The high precision and speed of laser welding lead to significant improvements in productivity, allowing for faster turnaround times on projects. The minimal heat input reduces the risk of warping and deformation, which is particularly beneficial when working with thin materials or heat-sensitive components, ultimately reducing rework and material waste. This precision is especially valuable in sectors where tight tolerances are critical.

Furthermore, the ability to perform high-quality welds on-site or in challenging locations provides considerable operational flexibility. This is particularly relevant for maintenance and repair operations where bringing components to a stationary welding station might be impractical or costly. The technology also often requires less operator skill to achieve consistent, high-quality welds compared to some traditional methods, potentially lowering training demands and broadening the pool of skilled technicians capable of performing these tasks within local services.

Industrial Applications of Laser Welding Across Sectors

Portable laser welding finds extensive application across a multitude of industrial sectors in Johannesburg. In the automotive industry, it is invaluable for repairing intricate components, fabricating custom parts, and performing precise bodywork without extensive disassembly. Manufacturing operations, from general fabrication to specialized electronics assembly, benefit from the ability to create strong, clean joints in a variety of materials with high repeatability.

The medical device sector, known for its stringent quality requirements, utilizes laser welding for joining small, delicate components where precision and biocompatibility are paramount. In the jewelry industry, the fine control offered by laser welding allows for intricate repairs and custom designs on precious metals. Even in construction, for specific, high-precision metalwork or repairs on installed structures, portable laser welders offer a practical and efficient solution, demonstrating their versatility across a broad economic spectrum.

Investing in portable laser welding technology involves considering various factors, including the machine’s power output, feature set, and the manufacturer’s reputation. The initial cost can vary significantly based on these specifications, with entry-level systems offering fundamental capabilities and high-performance models providing advanced features and greater power for demanding industrial applications. Businesses should evaluate their specific needs and projected usage to determine the most suitable investment.

| Product/Service | Category/Features | Estimated Cost (ZAR) |

|---|---|---|

| Entry-Level Portable Laser Welder | Basic functionality, lower power, air-cooled | R 150,000 - R 300,000 |

| Mid-Range Portable Laser Welder | Increased power, advanced controls, water-cooled | R 300,000 - R 600,000 |

| High-Performance Portable Laser Welder | High power, specialized features, automation options | R 600,000 - R 1,200,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The integration of portable laser welders into Johannesburg’s industrial practices signifies a move towards more refined and efficient production and repair processes. These machines offer a compelling combination of precision, speed, and versatility, making them a valuable asset for businesses aiming to enhance their operational capabilities. As technology continues to advance, the role of portable laser welding is likely to expand further, contributing to higher quality output and greater productivity across various sectors in the region.