Portable laser welders improve accuracy and efficiency in Pietermaritzburg

In Pietermaritzburg, portable laser welders are transforming the welding landscape, improving accuracy, saving time, and reducing costs. This technology is particularly beneficial in several sectors, including manufacturing and construction. A closer look at the different models, pricing structures, and practical applications reveals their growing importance in welding manufacturing processes. Furthermore, effective welding training for workers is essential to maximize the potential of these advanced machines.

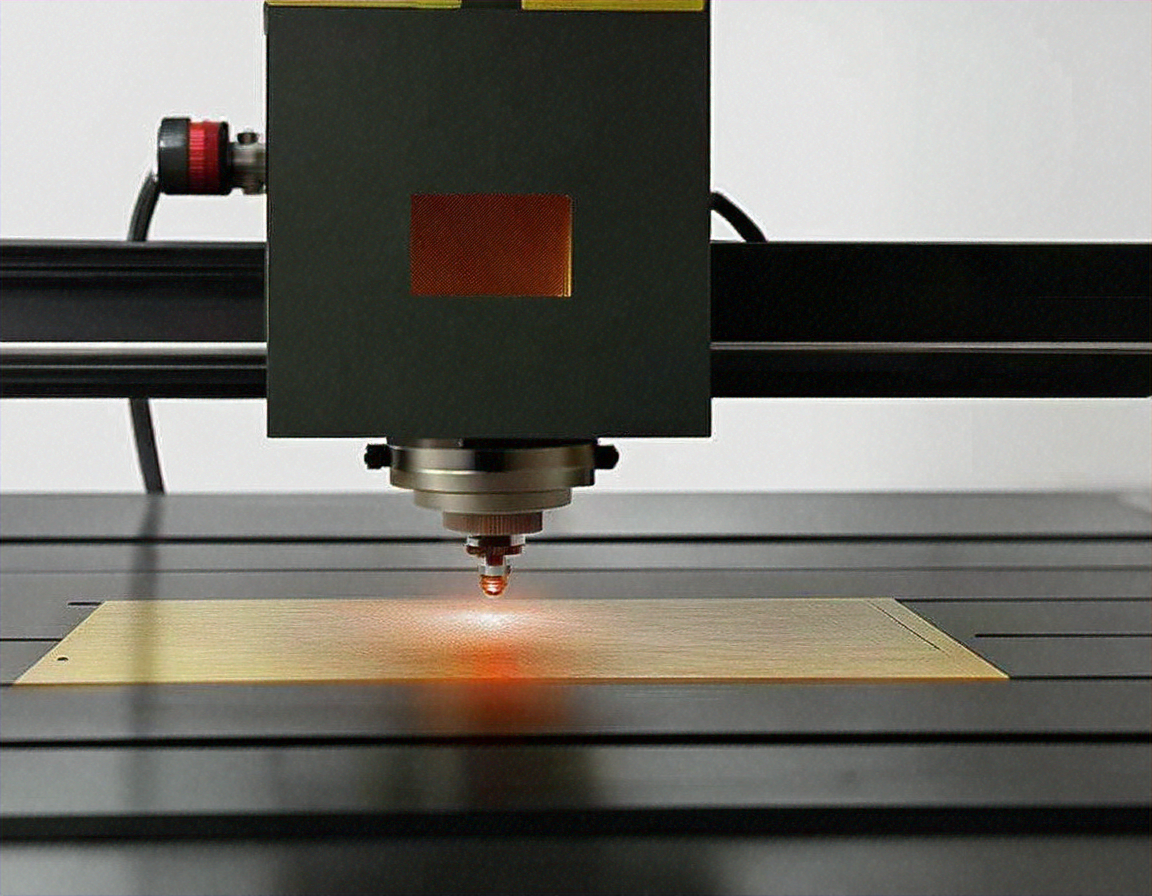

How Portable Laser Welding Machines Work

Portable laser welding machines operate by generating a concentrated beam of coherent light through a laser diode or fiber laser system. The laser beam is focused through precision optics onto the workpiece surface, creating intense localized heat that melts the base materials. Unlike conventional welding methods that rely on electrical arcs or gas flames, laser welding provides exceptional control over the heat-affected zone, resulting in minimal thermal distortion and superior weld quality.

The portable units typically incorporate handheld welding heads connected to compact laser generators via flexible fiber optic cables. This configuration allows operators to maneuver easily around complex workpieces while maintaining consistent beam delivery. Advanced models feature real-time power adjustment capabilities, enabling welders to modify parameters instantly based on material thickness and joint requirements.

Advantages of Portable Laser Welding in Pietermaritzburg Industry

Local manufacturing businesses in Pietermaritzburg are discovering numerous benefits from implementing portable laser welding technology. The precision offered by these systems significantly reduces material waste and rework requirements, leading to improved production efficiency and cost savings. The narrow heat-affected zone characteristic of laser welding preserves the mechanical properties of surrounding materials, particularly important when working with heat-sensitive alloys and thin-gauge metals.

The mobility aspect proves invaluable for maintenance and repair operations in industrial facilities where moving large components to fixed welding stations would be impractical or impossible. Operators can perform high-quality repairs on equipment in place, minimizing downtime and production interruptions. Additionally, the clean welding process eliminates the need for extensive post-weld cleaning and finishing operations commonly required with traditional welding methods.

Applications of Laser Welding in Various Industrial Sectors

The versatility of portable laser welding technology extends across multiple industrial sectors throughout the Pietermaritzburg region. In the automotive industry, these systems excel at joining dissimilar metals, welding thin-walled components, and performing precision repairs on vehicle frames and body panels. The aerospace sector utilizes laser welding for critical applications requiring exceptional weld quality and minimal heat distortion, particularly when working with titanium and aluminum alloys.

Manufacturing facilities producing medical devices and precision instruments benefit from the sterile welding environment created by laser systems, as the process generates minimal spatter and contamination. The food processing industry employs laser welding for stainless steel equipment fabrication and repair, where hygiene requirements demand smooth, crevice-free weld profiles that are easily achievable with laser technology.

| Equipment Type | Manufacturer | Power Range | Cost Estimation |

|---|---|---|---|

| Handheld Fiber Laser Welder | IPG Photonics | 1000-2000W | R180,000 - R350,000 |

| Portable Diode Laser System | Trumpf | 500-1500W | R120,000 - R280,000 |

| Mobile Laser Welding Unit | Coherent | 1500-3000W | R250,000 - R450,000 |

| Compact Fiber Laser Welder | Raycus | 1000-2000W | R150,000 - R320,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

The implementation of portable laser welding technology in Pietermaritzburg’s industrial landscape continues to expand as businesses recognize the long-term benefits of improved weld quality, reduced operating costs, and enhanced operational flexibility. The technology’s ability to deliver consistent results across various materials and applications positions it as a valuable investment for forward-thinking manufacturers seeking competitive advantages in today’s demanding market environment.