Portable laser welders improve accuracy and efficiency in Pretoria

In Pretoria, portable laser welders are transforming the welding landscape, improving accuracy, saving time, and reducing costs. This technology is particularly beneficial in several sectors, including manufacturing and construction. A closer look at the different models, pricing structures, and practical applications reveals their growing importance in welding manufacturing processes. Furthermore, effective welding training for workers is essential to maximize the potential of these advanced machines.

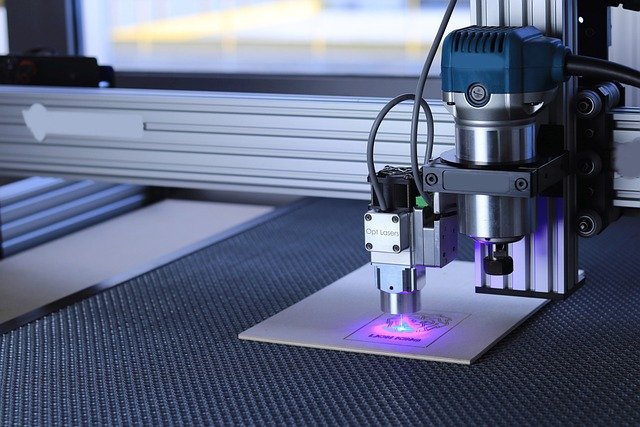

How Portable Laser Welding Machines Work

Portable laser welding machines operate on the principle of focused light energy. A high-power laser beam, typically generated by a fiber laser, is directed onto the material’s surface. This concentrated energy rapidly heats and melts the material at the point of contact, creating a molten pool that fuses the parts together. The key to their portability lies in their compact design, often featuring a handheld welding gun connected to a main unit via a flexible fiber optic cable. This allows operators to bring the welding tool directly to the workpiece, even in confined spaces or on large, immovable structures.

These systems offer precise control over parameters such as laser power, pulse duration, and spot size, enabling operators to achieve consistent and high-quality welds. The process is largely automated or semi-automated, reducing the reliance on extensive operator skill compared to some conventional welding techniques. This focus on controlled energy delivery minimizes heat input into the surrounding material, which helps to prevent distortion and discoloration, crucial for many delicate applications.

Advantages of Portable Laser Welding in Pretoria Industry

The adoption of portable laser welding offers several compelling advantages for industries within Pretoria. One primary benefit is the exceptional precision and accuracy achieved, leading to cleaner, stronger, and aesthetically superior welds. This is particularly valuable for sectors requiring high-quality finishes or working with thin materials where minimal heat affected zones are critical.

Furthermore, the speed of laser welding can significantly boost productivity. The rapid melting and solidification process allows for faster completion of welding tasks, reducing project timelines. Its portability allows for on-site repairs and fabrication, eliminating the need to transport large components to a stationary welding station. This flexibility is highly beneficial for diverse industries in the Pretoria area, from automotive repair to general fabrication and even maintenance in mining operations, where mobility is a significant asset. The minimal post-weld cleanup required also contributes to overall efficiency and cost savings.

Applications of Laser Welding in Various Industrial Sectors

Portable laser welding technology finds extensive applications across a wide array of industrial sectors, demonstrating its versatility and adaptability. In the automotive industry, it is used for precise repairs on vehicle bodies, engine components, and specialized parts, where its ability to work with various metals and minimize distortion is highly valued. The aerospace sector benefits from its precision for critical component assembly and repair, ensuring structural integrity and performance.

Medical device manufacturing utilizes laser welding for joining intricate and delicate components, often with biocompatible materials, demanding extreme accuracy and cleanliness. The jewelry industry also employs laser welders for fine, detailed work on precious metals, enabling seamless repairs and custom designs. Beyond these, general fabrication shops, electronics manufacturing, and even the repair of industrial machinery in Pretoria can leverage portable laser welders for efficient, high-quality joining of diverse materials, including stainless steel, aluminum, copper, and various alloys.

Portable laser welding machines represent a significant investment, with costs varying widely based on power output, features, and brand. Entry-level systems designed for lighter industrial use might be more accessible, while high-power units intended for continuous heavy-duty applications would naturally command a higher price point. Potential buyers should consider their specific application needs, material types, and required duty cycle when evaluating options.

| Product/Service | Provider (Generic) | Cost Estimation (ZAR) |

|---|---|---|

| Entry-Level Portable Welder | Specialized Welding Equipment | R150,000 - R300,000 |

| Mid-Range Portable Welder | Industrial Machinery Distributor | R300,000 - R600,000 |

| High-Power Portable Welder | Advanced Fabrication Solutions | R600,000 - R1,200,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Understanding the Investment in Portable Laser Welding

While the initial investment in a portable laser welding machine can be significant, the long-term benefits often outweigh the upfront costs. The enhanced precision reduces material waste and rework, while increased efficiency leads to faster project completion and higher throughput. Reduced reliance on consumables like filler wire in many applications also contributes to operational savings. Furthermore, the ability to perform repairs on-site minimizes downtime for machinery and equipment, a crucial factor for productivity in industrial settings around Pretoria. Businesses should evaluate the potential return on investment by considering factors such as labor savings, quality improvements, and expanded service capabilities.

Maintenance and Training for Optimal Performance

To ensure optimal performance and longevity of portable laser welding machines, proper maintenance and operator training are essential. Regular cleaning of optical components, checking connections, and adherence to manufacturer guidelines are crucial for consistent output and safety. Comprehensive training programs for operators can help them master the nuances of laser welding, including material handling, parameter setting, and safety protocols. Investing in proper training ensures that businesses in Pretoria can maximize the benefits of this advanced technology, leading to safer operations, higher quality welds, and a more skilled workforce capable of handling diverse welding challenges.

Portable laser welders offer a transformative approach to welding, bringing unparalleled precision, speed, and flexibility to various industrial applications. Their ability to deliver high-quality results with minimal heat input and their inherent mobility make them an increasingly attractive option for businesses in Pretoria seeking to enhance their manufacturing and repair capabilities. As technology continues to evolve, these systems are poised to play an even more significant role in shaping the future of welding processes across diverse sectors.